Concrete Testing

Our range of products includes :Compression Testing Machine Hand Operated

|

Features:

- International quality

- Easy to use and maintain

- Reasonable price

- Highly durable

Specifications:

- Size: 5cm x 5cm x 5cm, 7.06 x 7.06cm, 10cm x 10cm x 10cm, and 15cm x 15cm x 15cm

- Height: 10 x 20cm and 15 x 30cm

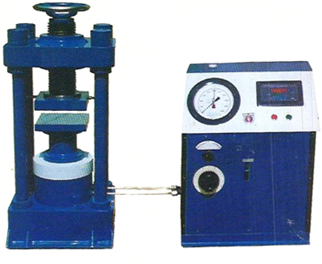

Compression Testing Machine-Digital

|

The digital compression testing machine has been designed to meet the need for a simple, economic and reliable means to test concrete for its compressive strength. The design expressive of simplicity, both of construction and operation, makes the machine easy to use and maintain. The unit is compact, making it useful for site and Laboratory applications. The digital machines are provided with a pace rate controller, to enable maintain a constant of loading.

- High stability four column load frame

- Each frame tested for stability and alignment to avoid tension failure during a test and to ensure centre loading

- Standard Platens for 3 X 6”/ 4 X 8” and 6 X 12” cylinders included.

- A precise large diameter spherical upper platen for optimum results

- Variety of optional accessories for cubes, blocks, bricks and flexure test available

- Motorized hydraulic power pack or pumping unit with rapid approach and automatic overload protection

- Comes standard with safety Guards on all four sides

The Complete unit comprises a Loading Unit which is of fully welded or two pillar model construction having a cross-head with a spherical seated platen. The lower platen is attached to the top of the piston. The Loading capacity is of 2000 KN, Cubes up to 200 mm & Cylinders up to 150 mm Dia X 300 mm Height can be tested using the appropriate spacers.

Pumping Unit with choice of compact power pack attached closely to the loading unit or separate hydraulic pumping unit, attached to the loading unit by high pressure hydraulic flexible hose pipe. The pump facilitates rapid approach of the platens for daylight closure and also provides comprehensive control over the application of load. A control valve provides fine control over the loading rate for accurate pacing.

Maximum load is held and retained for approx. 15 min, unless cancelled, using the panel mounted reset switch. Pace rate set for running the test can be maintained manually.

Model With digital Readout and pace rate Controller

| Type of Pumping | Electrical |

|---|---|

| LoadingRange | 2000KN |

| Least Count | 1 KN |

| Max. Clearance Between Platen | 370mm |

| Max. Clearance Between Side Platen | 340mm |

| Platen Size | 220 mm sq. |

| Piston Stroke | 215.00 mm |

Cube Mould

|

Complete with base plate. The faces of the mould are machined flat to +/- 0.02mm accuracy and finished to within +/- 0.2mm of specified dimensions. Material for construction of moulds is Cast Iron or Mild steel. The moulds are stout enough to prevent distortion and facilitate the removal of the moulded specimen without damage. The Moulds are so machined that when they are assembled ready for use, the dimensions and internal faces are accurate within the specified limits. Internal faces of the moulds are smooth.

The base plate is attached to the mould by cleats .The parts of the mould, when assembled, are positively and rigidly held together during filling, subsequent handling and vibration where applicable.

SIZES AVAILABLE : 50MM/ 100MM/ 150MM

CUBE MOULD 7.06 CMS(FOR CEMENT MORTAR)

As per IS : 10086-1982, The cube mould is so constructed so as to facilitate separation into two parts. The mass of the mould together with the base plate will be 2.8 +/- 0.2 kg. Material for construction of these moulds is mild steel.BEAM MOULDS

For casting concrete specimens for flexural tests. The mould is made of 4 plates assembled together. Each mould with base plate, made of Mild Steel. Faced are machined flat to +/-0.2mm and finished in size to 0.2mm. AS PER IS: 516.Slump Test Apparatus

|

The device is a hollow cone-shaped mould. The mold is filled in three layers of each volume. Each layer is rodded with a 16mm steel rod 25 times. The mould is then lifted away and the change in the height of the concrete is measured against the mould. The slump test is a measure of the resistance of concrete to flow under it own weight.

The apparatus comprise of a slump cone with handles made of mild steel sheet, a chrome plated steel tamping rod of 16 mm diameter X 600 mm long, rounded off at one end, with a scale marked on it and a steel base plate with a carrying handle.

The mould for the test specimen will be in the form of frustum of a cone having the following internal dimensions as follows.

| Dimensions | Cm. |

|---|---|

| Bottom diameter | 20 |

| Top diameter | 10 |

| Height | 30 |

Vibrating Table

|

The Vibrating table is entirely constructed of thick steel. The table top is made of thick mild steel plate and has stops along its edges to prevent moulds from walking off the table during operation. A cross arm adjustable on a vertical rod at the centre of the table is provided to hold the moulds while operating the table. The variable pitch pulley arrangement permits the variation of frequency between maximum of 3600 vibrations down to 2600 vibrations per minute. A speed regulation handle is provided for increasing or decreasing the frequency. The vibrator is mounted on cushioned steel vibrating deck. A switch is provided for starting the motor. Operation on 440 V, three phase, A.C. supply

- 50 X 50 CMS

- 60 x 60 CMS

- 75 x 75 CMS

- 100 x 100 CMS

Vibrating Hammer

|

Features:

- Vibration less performance

- Durable

- Strong

Accelerated Curing Tank

|

The rate of gain of strength of concrete depends on the reaction rate of cement and additions with water (Hydration). In common with all chemical reactions, the rate of reaction depends on reaction of temp. Higher reaction temperature gives higher rate of reaction e.g. the concrete gains strength more rapidly when its temp. is higher. Accelerated curing is the process by which the temperature of the concrete is raised artificially by applying external heat to speed up the rate of gain in strength.

The test method covers procedures for curing test specimens of concrete stored under conditions intended to accelerate the development of strength. The procedures are: Procedure A- Warm Water Method, Procedure B-Boiling Water Method

Accelerated Curing Tank having capacity to accommodate 6/12/18 Concrete Cubes of 150mm size with a facility for accelerated curing by Boiling water method up to temperature range : 100 +/- 2 deg.C as per IS standard IS : 9013. Also it will have capacity for curing by warm water method at temperature 55 +/- 2 deg.C

Tank will consist of a rectangular double walled metal cabinet, inside lined with stainless steel, outer powder coated. Easily replaceable high Wattage heaters are mounted in side the chamber. A slow speed stirrer is provided to circulate water inside the chamber to maintain the uniform temperature of water. A strong stainless steel perforated platform is provided for keeping the cubes and also have a lid with lifting handle to cover the chamber.

The temperature is indicated and controlled by a DIGITAL auto tuning PID Temp. Controller with soak timer to control the duration of heating and then to shut down the system without manual attendance. The front panel will have power supply indicating lamp, control action indication lamp and one main switch. Suitable for operation on 220 V, 50 Hz single phase, AC supply or 440 V 50 Hz, three phase AC supply, for bigger size of curing tank.

Rubber hand Gloves. Spare Heaters. Low water Level cut off device to safeguard heaters against low water level burn out In built refrigeration system for curing at 27 deg C

Concrete Mixer- Laboratory type

|

The Concrete Mixers are available in two versions for Laboratory or field use. The field models are hand operated. This portable concrete mixer has rubber tyred wheelsand a towing tongue so that it can be towed and moved around by hand. Its rotationis powered by single-phase electric motor or by hand . The lever allows the concrete to be tipped into a wheel-barrowor mixing pan. The driving shaft is mounted on sealed ball bearing The counter balanced drum swivels and tilt 360° for easy and complete discharge.

Specifications

| Drum Capacity | 3 cubic feet approximately |

|---|---|

| Drum material | Cast Iron or mild steel |

| Mixer Capacity | 2 cubic feet approximately |

| Drum Rotation | 20-22 |

| Motor Power | 0.5 HP single Phase AC Supply / Hand operation |

Wheel Barrow, Mixing Pan, concrete Scoop

Concrete Permeability Apparatus

|

The set up consist of permeability cell, water reservoir and pressure lines, with glass bottles.

Permeability Cell

Consists of a metal cylinder with a ledge at the bottom for retaining the specimen, a flange at the top, removable cover plate and a funnel. A rubber gasket is seated in matching grooves, between the cell and the cover plate, to render the joint water tight. Internal working size of the cell will be 100mm dia X 100mm hight.Water Reservoir

Consists of a length of metal pipe, 50 to 100 mm in diameter and about 500 mm long. The reservoir fitted with a graduated side arm gauge-glass for admitting water and compressed air and a cock for drainage, bleeding and connection to the permeability cell.Pressure Lines

Heavy duty armored rubber hose with end fittings. Complete with glass bottles but without compressor. For specimen size 100 X 100 mmConcrete permeability tester for three specimen of (100mm dia x 100mm height) or (150mm dia x 150mm height) or (150mm cube) is also available.

Compaction Factor Apparatus

|

The apparatus, consist of a rigid frame that supports two conical hoppers vertically aligned above each other and mounted above a cylinder. The top hopper is slightly larger than the bottom hopper, while the cylinder is smaller in volume than both hoppers. To perform the test, the top hopper is filled with concrete but not compacted. The door on the bottom of the top hopper is opened and the concrete is allowed to drop into the lower hopper. Once all of the concrete has fallen from the top hopper, the door on the lower hopper is opened to allow the concrete to fall to the bottom cylinder. The excess concrete is carefully struck off the top of the cylinder and the mass of the concrete in the cylinder is recorded. This mass is compared to the mass of fully compacted concrete in the same cylinder achieved with hand rodding or vibration.Complete with trowel and tamping bar 0-60 cms long X 16mm dia.

- Concrete Scoop

- Straight Edge

- Weighing Balance